Introduction

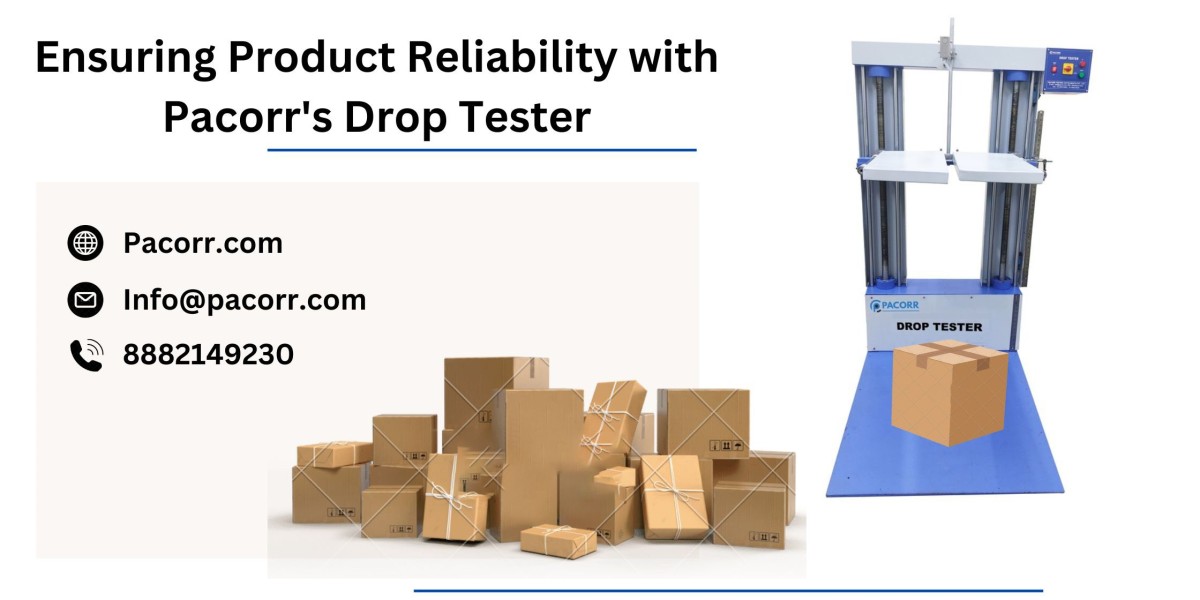

In today's competitive market, product safety and packaging durability are critical factors that manufacturers must consider. Whether shipping fragile electronics, pharmaceuticals, or consumer goods, ensuring packaging can withstand impacts, drops, and rough handling is essential. A Drop Tester is a specialized testing machine designed to evaluate a product's ability to endure accidental falls and transport conditions .

At Pacorr.com , we offer high-precision Drop Tester that helps manufacturers enhance packaging durability, minimize product damage, and comply with industry standards .

Why is Drop Testing Important?

1. Prevents Product Damage During Transit

Products often go through rigorous shipping and handling before reaching consumers. Drop testing simulates real-world conditions , helping manufacturers design stronger and more resilient packaging .

2. Ensures Compliance with Industry Standards

Many industries, including electronics, pharmaceuticals, and consumer goods, follow strict packaging durability guidelines set by organizations like ASTM, ISO, and ISTA. A Drop Tester ensures compliance with these standards.

3. Reduces Returns and Customer Complaints

Damaged goods lead to customer dissatisfaction, increased returns, and brand reputation damage. Drop testing helps manufacturers identify weak points in packaging, reducing product failures and financial losses.

4. Saves Costs on Packaging Materials

Drop testing allows manufacturers to optimize packaging design—balancing protection and cost-efficiency. By testing the impact resistance of packaging, companies can select the most effective and economical materials.

How Does a Drop Tester Work?

A Drop Tester evaluates a product's impact resistance by dropping it from a controlled height onto a solid surface. The test typically includes:

- Securing the product or package on the testing platform

- Lifting the sample to a pre-set height

- Dropping the sample to simulate real-world impact

- Inspecting damage, breakage, or performance failure

Data collected from the test helps manufacturers improve packaging designs and enhance product safety.

Types of Drop Testers

1. Free-Fall Drop Tester

✔️ Simulates free-fall impact from various heights

✔️ Ideal for consumer electronics, mobile phones, and packaged goods

✔️ Ensures structural durability of products and packaging

2. Edge & Corner Drop Tester

✔️ Tests impact resistance on corners, edges, and flat surfaces

✔️ Best for cartons, boxes, and fragile packaging

✔️ Ensures damage protection during transport

3. Heavy-Duty Drop Tester

✔️ Designed for large and heavy products

✔️ Tests wooden crates, industrial packaging, and automotive parts

✔️ Suitable for bulk shipping and export goods

Industries That Benefit from Drop Testing

1. E-Commerce & Retail

Drop testing ensures that online-ordered products arrive intact, reducing return rates and customer dissatisfaction.

2. Electronics Industry

Devices like smartphones, laptops, and home appliances require impact resistance testing to prevent damage during accidental drops.

3. Pharmaceutical & Medical Equipment

Drop testing ensures safe transport of medicines, glass vials, and medical devices, preventing contamination and breakage.

4. Packaging & Logistics

Corrugated boxes, cartons, and containers must withstand rough handling during warehousing, shipping, and delivery . Drop testing guarantees packaging durability.

How to Choose the Right Drop Tester at Pacorr.com

When selecting a Drop Tester Price , consider:

✔️ Drop Height Range – Adjustable height settings for different impact levels

✔️ Sample Size & Weight Capacity – Ensure compatibility with your product dimensions

✔️ Drop Surface Variability – Choose models with customizable drop angles and surfaces

✔️ Ease of Operation – User-friendly controls for efficient testing

Conclusion

A Drop Tester is a crucial tool for assessing product durability, improving packaging, and reducing damage risks . Whether you're in e-commerce, electronics, pharmaceuticals, or logistics , drop testing enhances product safety and ensures customer satisfaction .

At Pacorr.com , we provide advanced Drop Testers designed to meet industry standards and real-world packaging challenges . Visit Pacorr.com today to explore our range of testing solutions and protect your products! ?