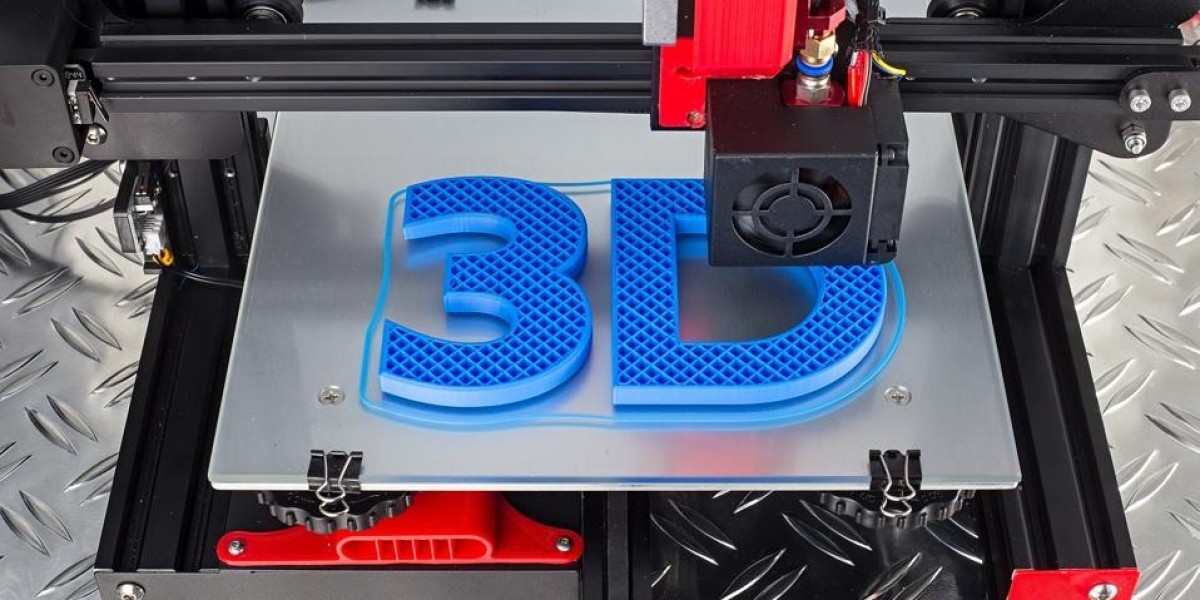

Overview of Procurement Intelligence in the 3D Printing Ecosystem

Procurement Intelligence for 3D printing Market involves leveraging data, market trends, and supplier analysis to make smarter sourcing decisions. With rapid advancements in additive manufacturing technologies, procurement professionals are under pressure to optimize costs and ensure timely availability of raw materials like polymers, metals, and resin. Understanding supplier capabilities, industry innovations, and market pricing is crucial. Procurement intelligence helps identify strategic sourcing opportunities, assess risks, and establish sustainable vendor relationships. It also enables businesses to align purchases with technological trends and compliance regulations, ensuring competitiveness in an evolving market landscape.

Key Suppliers and Market Dynamics

The 3D printing supply chain is dominated by leading global manufacturers and specialized material providers. Companies like HP, Stratasys, EOS, and 3D Systems play an integral role in hardware supply, while BASF and Evonik lead material innovations. Procurement intelligence tracks supplier financials, capacity, geographical reach, and innovation pipeline. It provides insights into pricing fluctuations, supplier risks, and geopolitical factors affecting the supply chain. Understanding such dynamics allows buyers to negotiate better contracts, diversify sources, and build supplier resilience, avoiding disruptions from raw material shortages or regulatory changes in key markets like the US, EU, and Asia.

Cost Structures and Price Forecasting

Procurement professionals rely on cost intelligence to monitor fluctuation in raw material prices, labor, energy costs, and logistics. In the 3D printing industry, the prices of key inputs such as PLA, ABS, titanium, and photopolymers are influenced by global demand, supply-chain bottlenecks, and energy prices. Procurement intelligence platforms offer cost breakdowns and forecasting models using real-time market data. This enables companies to budget more accurately and time purchases strategically. Over the next few years, cost trends suggest that metal powders will see increased demand, pushing prices upward, while thermoplastic prices may stabilize due to scalable production techniques.

Innovation and Technology Impact on Procurement

Technological innovation is transforming procurement strategies in the 3D printing sector. Advancements like multi-material printing, speed enhancements, and AI-driven design influence the types of equipment and materials companies must procure. Procurement intelligence keeps track of new technologies, patents, and R&D investments to help decision-makers stay ahead of the curve. It also provides strategic insights into equipment lifecycle, depreciation, and maintenance costs. By leveraging such intelligence, companies can identify optimal technological investments and align procurement with automated processes, reducing waste and improving overall return on investment in a highly competitive landscape.

Sustainability and Regulatory Considerations

Sustainable and compliant sourcing is an emerging priority for procurement in the 3D printing market. Regulatory frameworks around eco-friendly materials, waste disposal, and emissions are tightening, especially in developed regions. Procurement intelligence helps companies navigate these regulations by benchmarking suppliers' sustainability practices and compliance records. It supports responsible sourcing by identifying bio-based or recyclable material options and green-certified vendors. In addition, understanding environmental costs aids in supplier selection and risk mitigation. The integration of Environmental, Social & Governance (ESG) objectives into procurement strategies is now a competitive differentiator that positions companies as forward-thinking and responsible manufacturers.

Strategic Sourcing Recommendations and Future Outlook

Strategic sourcing in 3D printing depends on a combination of supplier agility, innovation capability, and geographical diversification. Procurement teams are advised to form strategic partnerships with vendors involved in advanced material R&D and maintain supply redundancy to manage disruptions. Investing in digital procurement tools and AI-driven analytics will further enhance decision-making. Future trends show a shift toward decentralized manufacturing, increasing demand for regional suppliers. With 3D printing anticipated to grow at a CAGR of over 20% through 2030, procurement intelligence will play a central role in optimizing supply chains, minimizing risks, and capitalizing on emerging technologies globally.