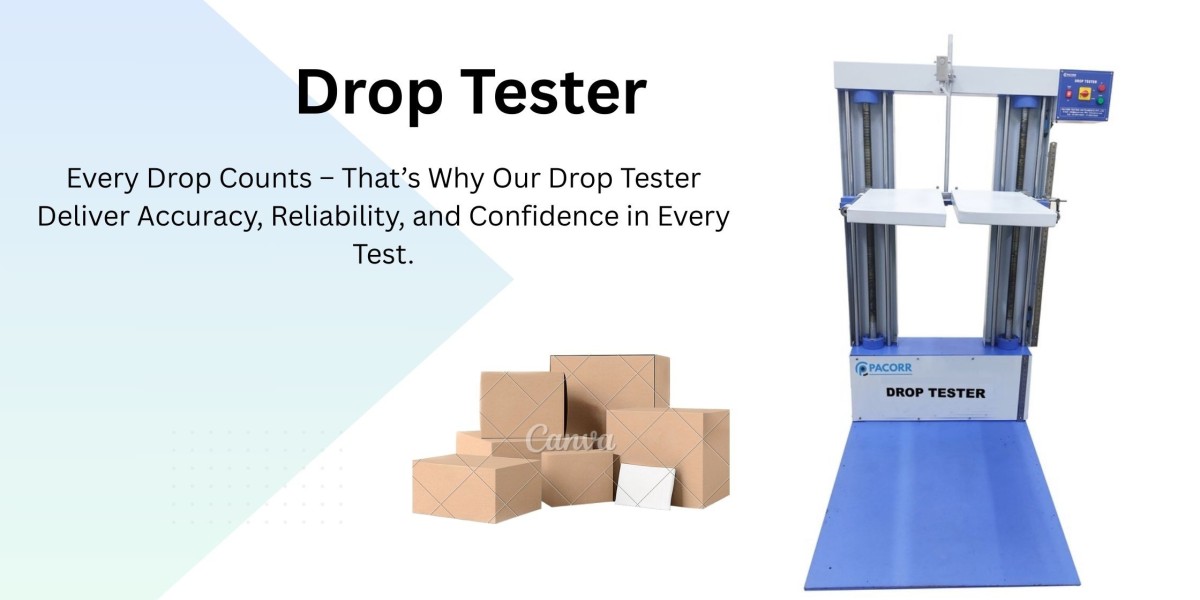

These testing tools allow businesses to evaluate packaging strength, ensure durability, and prevent costly product damage during transit.

Whether you need to test large, heavy-duty packaging or fragile, sensitive materials, Pacorr’s Drop Testers provide the precision, consistency, and flexibility to meet your packaging testing needs.

What is a Drop Tester and Why Is It Important for Packaging?

A Drop Tester simulates the impact forces packaging experiences during shipping. By dropping a sample package from a specified height onto a hard surface, it mimics the shock and stress packaging would face during transit. This test helps businesses determine if their packaging can protect their products from damage.

At Pacorr, we offer Drop Tester Pneumatic & Motorized that give you the ability to adjust the drop height and impact conditions, allowing for customizable testing scenarios. With these tools, businesses can ensure that their packaging will effectively protect products during shipping.

Pneumatic Drop Tester: Precision Testing for Heavy and Fragile Packaging

The Pneumatic Drop Tester uses compressed air to lift and drop the test sample. This model is ideal for testing larger and heavier packages, as well as fragile items that need extra precision during testing. The pneumatic system provides reliable control over the drop height, making it perfect for packaging that requires a more controlled drop process.

The Pneumatic Drop Tester is particularly useful for industries such as electronics, glass, and other products that require careful handling during shipping. It allows you to evaluate packaging performance with high precision.

Key Features of the Pneumatic Drop Tester:

Controlled Drop Mechanism: Uses compressed air for precise, repeatable drops.

Ideal for Large or Fragile Packaging: Perfect for testing heavy or sensitive packaging materials that need careful handling.

Adjustable Drop Heights: Customize the drop height to simulate different shipping impacts.

Versatile Testing: Suitable for various types of packaging, from small fragile items to larger, bulkier packages.

Motorized Drop Tester: Fast, Automated Testing for High-Volume Needs

The Motorized Drop Tester automates the lifting and dropping process using an electric motor, providing consistent and quick results. This model is ideal for businesses that require high-efficiency testing and need to conduct multiple tests in a short time. The motorized system reduces manual effort and increases testing speed, making it ideal for high-volume environments.

The Motorized Drop Tester is perfect for industries such as e-commerce, food packaging, and manufacturing, where quick, automated testing is necessary. It provides accurate and repeatable results without the need for constant supervision.

Key Features of the Motorized Drop Tester:

Automated Testing Process: The electric motor automates the lifting and dropping of the sample, ensuring consistency and efficiency.

High-Efficiency Testing: Ideal for high-volume testing, reducing time and labor.

Adjustable Drop Heights: Easily adjust the drop height to test packaging under various conditions.

Fast and Efficient: Automated system allows for quick testing without manual intervention.

Benefits of Pacorr Drop Testers

Both the Pneumatic and Motorized Drop Testers provide several key benefits for businesses that are focused on improving packaging quality and protecting products during transit.

1. Reliable and Repeatable Results

Both models offer precise, repeatable testing, ensuring that your packaging is tested under controlled conditions. This helps you gather reliable data, which is essential for making informed decisions about packaging improvements.

2. Flexible Testing Conditions

The Pneumatic and Motorized Drop Testers are highly customizable. You can adjust the drop height and simulate various shipping conditions to test how your packaging holds up under different impacts.

3. Cost Savings Through Damage Prevention

By identifying weaknesses in packaging early, you can prevent costly product damage, returns, and customer complaints. This proactive testing approach helps businesses reduce costs and improve the overall efficiency of their packaging process.

4. Improved Packaging Design

The data from the Drop Testers helps businesses identify areas where their packaging may be lacking in strength or protection. This information can be used to refine packaging designs, materials, and structures, ensuring better protection during transit.

5. Compliance with Industry Standards

Both Pneumatic and Motorized Drop Testers comply with relevant industry standards for packaging testing, ensuring that your packaging meets all necessary safety and durability regulations.

Which Drop Tester Is Right for Your Business?

Choosing between the Pneumatic and Motorized Drop Testers depends on your specific needs:

Pneumatic Drop Tester: If your packaging requires precise control and you need to test heavy or fragile items, the Pneumatic Drop Tester is the best option. It provides controlled drops and is ideal for sensitive or large packaging materials.

Motorized Drop Tester: If you require automated, high-efficiency testing with minimal manual input, the Motorized Drop Tester is the better choice. This version is perfect for industries that need to conduct rapid testing on a large number of packaging samples.

Conclusion: Optimize Your Packaging Testing with Pacorr’s Drop Testers

At Pacorr, we provide Pneumatic and Motorized Drop Testers to help businesses ensure that their packaging materials perform under real-world shipping conditions. Whether you choose the Pneumatic Drop Tester for controlled testing or the Drop Tester Motorized and Pneumatic for high-volume efficiency, both options offer the precision, flexibility, and reliability needed to optimize your packaging testing processes.

By investing in Pacorr’s Drop Testers, you can improve your packaging designs, reduce shipping damage, and increase customer satisfaction. Visit pacorr.com today to learn more about our Pneumatic and Motorized Drop Testers and discover the perfect solution for your packaging durability testing needs.

Frequently Asked Questions (FAQs)

1. What’s the difference between the Pneumatic and Motorized Drop Testers?

The Pneumatic Drop Tester uses compressed air for controlled, precise drops, making it ideal for testing heavy or fragile packaging. The Motorized Drop Tester automates the process using an electric motor, making it perfect for high-volume, fast testing.

2. Which version is best for high-volume testing?

The Motorized Drop Tester is the best option for high-volume testing as it automates the process, making it faster and more efficient.

3. Can both models handle different packaging sizes?

Yes, both the Pneumatic and Motorized Drop Testers can accommodate a wide range of packaging sizes, from small fragile items to larger, bulkier packages.

4. How do I decide between the Pneumatic and Motorized models?

If you need precise control for large or delicate packaging, the Pneumatic Drop Tester is the better choice. If you need automated, efficient testing for high-volume environments, the Drop Tester is ideal.

5. Are Pacorr Drop Testers compliant with industry standards?

Yes, both models meet industry standards for packaging testing, ensuring that your packaging meets necessary safety and durability regulations.