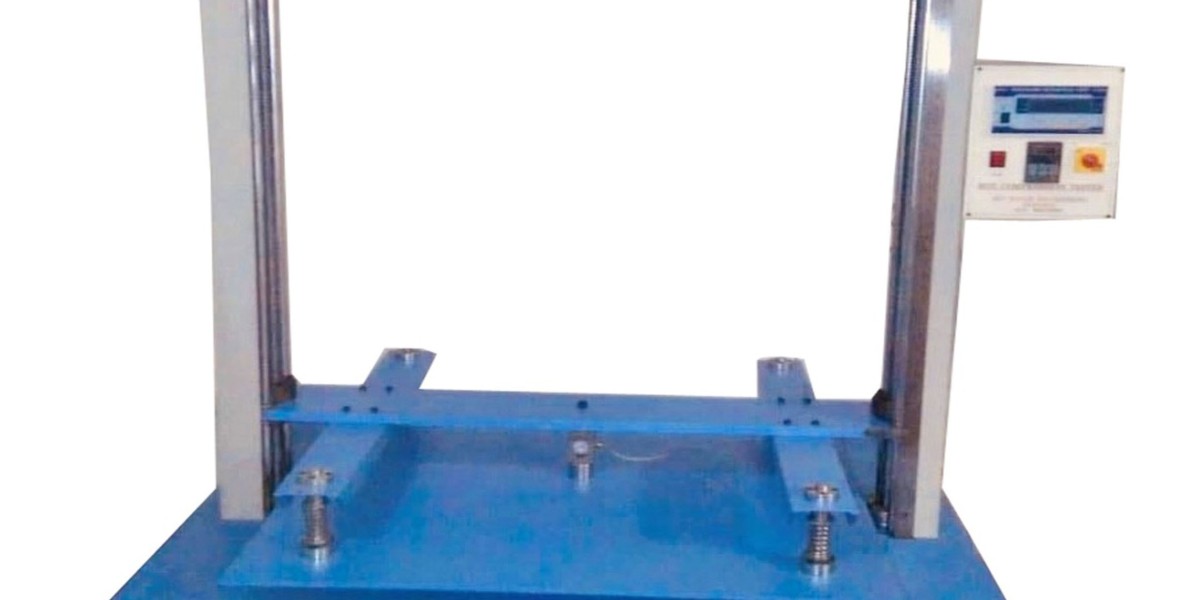

One of the most reliable instruments used for assessing the structural integrity of these packages is the Box Compression Tester (BCT) — and with modern advancements, the Box Compression Tester Computerized takes this process to an entirely new level.

At Labzenix.com, we specialize in providing state-of-the-art testing equipment that empowers industries to maintain top-tier quality standards. Here, we’ll explore both the manual and computerized versions of the Box Compression Tester, their applications, and how they benefit your operations.

What is a Box Compression Tester?

A Box Compression Tester is a device designed to evaluate the compression strength of corrugated boxes and similar packaging materials. The purpose of the test is to determine how much compressive load a box can endure before it deforms or collapses. This is especially critical for manufacturers, shippers, and retailers who rely on safe and sturdy packaging to protect products.

Key Features:

Rugged, high-precision construction

Adjustable compression plate size

Uniform load distribution system

Manual control with digital display

This tester helps in determining stacking strength, which is crucial for storage and transportation. Knowing a box’s compressive strength allows manufacturers to avoid over-engineering (which adds unnecessary cost) or under-engineering (which risks product damage).

Introducing the Box Compression Tester Computerized

Taking precision and convenience a step further, the Computerized Box Compression Tester incorporates digital technology to automate data collection, analysis, and reporting. This advanced version is ideal for high-volume production units, laboratories, and research facilities.

Features and Advantages:

Automated control system with real-time graphical data

User-friendly software interface for test programming

High-accuracy sensors to capture minute load changes

Data export capabilities for analysis and record-keeping

Multiple testing modes including peak load, deflection, and dwell time

With computerized testing, operators can track variations over time, perform batch testing, and generate instant test reports. It also reduces human error and ensures consistent results, making it a smart investment for companies aiming to meet global packaging standards like ISO, ASTM, or TAPPI.

Applications Across Industries

Whether you're in pharmaceuticals, e-commerce, electronics, FMCG, or automotive, ensuring that your packaging can withstand compressive forces is essential. Both versions of the Box Compression Tester are suitable for:

Corrugated boxes and cartons

Paperboard containers

Plastic crates and rigid packaging

Bulk shipping boxes

Palletized loads

For large-scale facilities or R&D centers, the computerized version delivers a streamlined workflow and comprehensive insights. For smaller setups or those just beginning with packaging quality control, the manual Box Compression Tester Price offers reliable performance at a lower cost.

Why Choose Labzenix.com?

At Labzenix.com, we understand that accurate testing is the backbone of reliable product packaging. Our Box Compression Testers are designed with precision engineering and robust materials to ensure longevity and consistent performance.

What You Get:

High-quality, calibrated instruments

Technical support and installation assistance

Customizable models based on your needs

Competitive pricing and warranty coverage

From small businesses to multinational corporations, our clients trust Labzenix for equipment that meets both technical and operational expectations.

Final Thoughts

The integrity of your packaging is non-negotiable — and a reliable Box Compression Tester is your first line of defense. Whether you opt for the standard model or the Box Compression Tester Computerized, investing in quality testing equipment ensures safety, compliance, and customer satisfaction.

Explore our range of testing solutions at Labzenix.com and take your packaging quality to the next level.